How to Safely Unload, Store and Install Roof Trusses

Safety is Pasquill’s number one priority, for both employees and customers and therefore we have produced a number of documents to help you improve safety on site, highlighting how to safely unload, store and install your roof trusses.

Unloading your Roof Trusses

It is your responsibility for providing the following:

- The right number of able bodies for the unloading of materials, with the right skills

- Barrier tape

- The necessary mechanical handling equipment – i.e. a crane or forklift

- A timber bearer (required for inverted trusses)

- Personal Protective Equipment (PPE) – hard hat, safety footwear, safety gloves, high visibility outerwear

Roof Trusses are generally delivered in tight bundles using bindings; your trussed rafters (also known as roof trusses) must be unloaded safely following the correct procedures, so it does not overstress the truss.

In most circumstance mechanical handling equipment, such as a forklift or a crane, is required to unload your trusses on site. It is your responsibility to ensure you have the correct mechanical handling equipment and labour on site when the trusses are delivered.

Mechanical handling equipment avoids the need for anyone to access the bed of the lorry, thus removing the risk of an injury. To assist contractors on site Pasquill use different coloured bandings or restraints to reduce the risk of the incorrect band or rope being cut.

We have a number of Safe Unloading documents to assist you when unloading your trusses on site. View the documents below or take a look at more in our Technical Library.

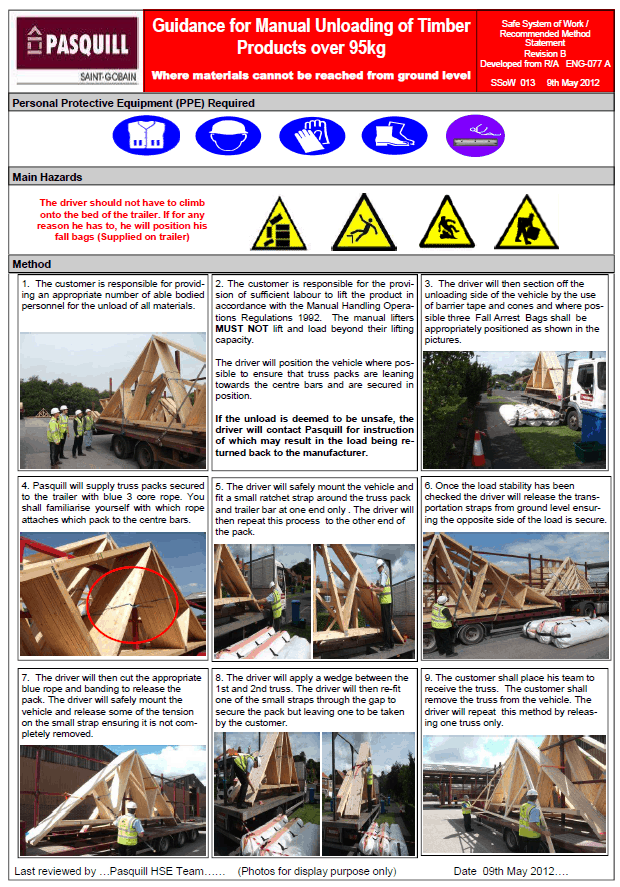

Safe Unloading of Timber Trusses over 95kg

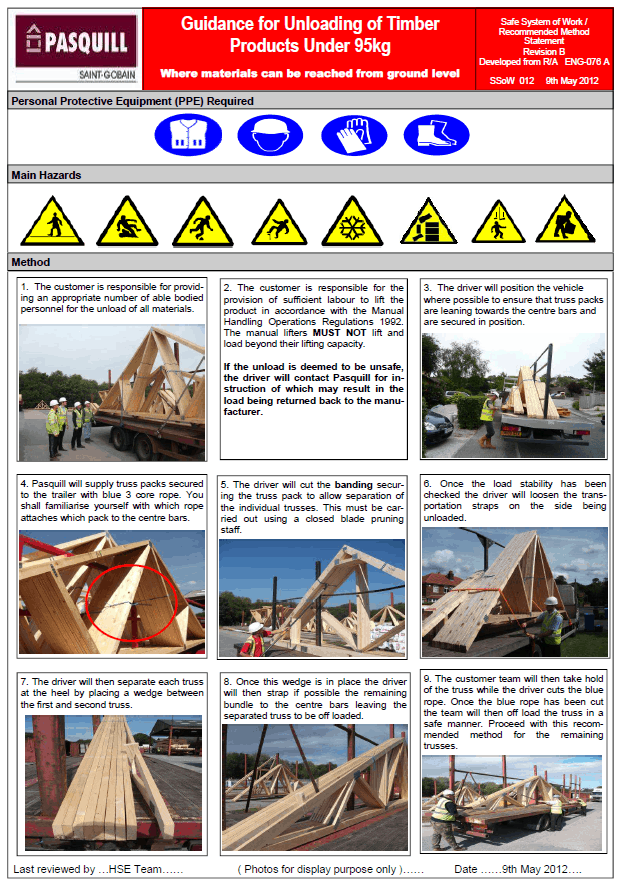

Safe Unloading of Timber Trusses under 95kg

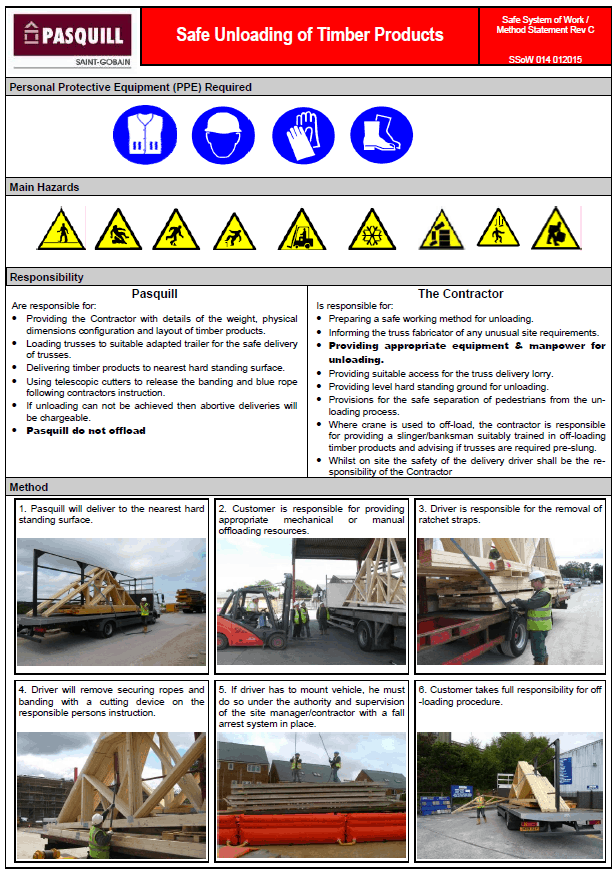

Safe Unloading of Timber Trusses

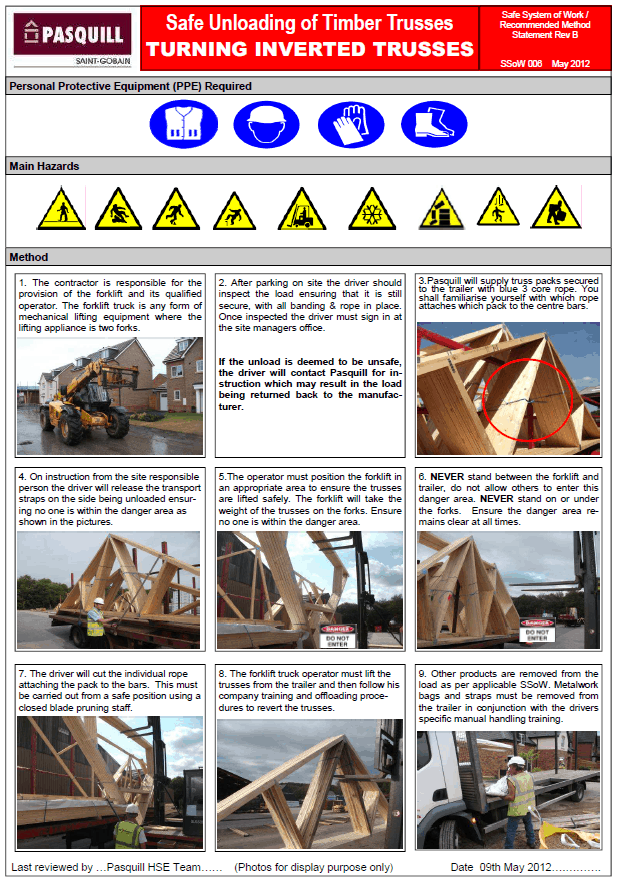

Safe Unloading of Timber Trusses Turning Inverted Trusses

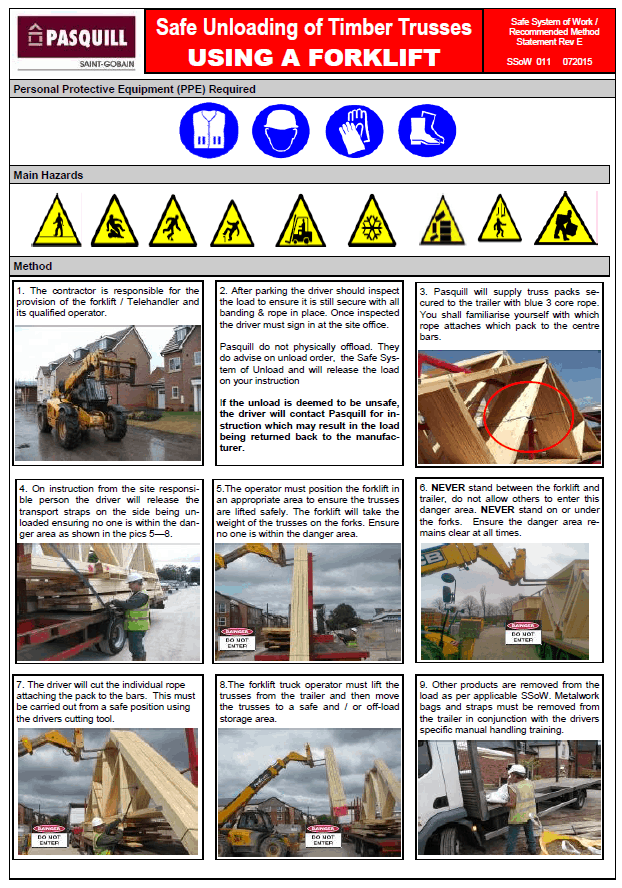

Safe Unloading of Timber Trusses Using a Forklift

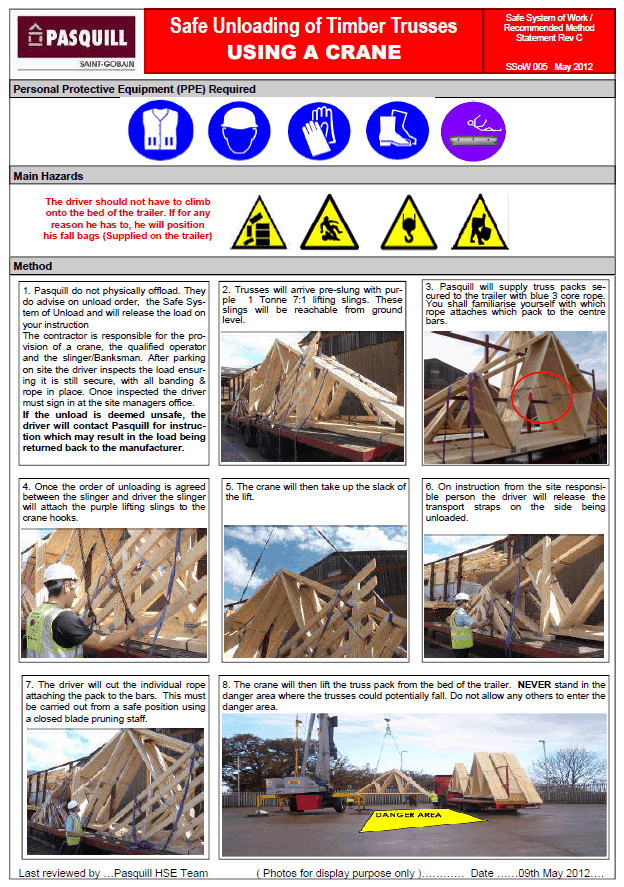

Safe Unloading of Timber Trusses Using a Crane