Timber Floor Construction Methods

So, you have decided on the perfect piece of timber. But, how will joists and floor cassettes help to construct it into flooring? In this article, we will be discussing all the different timber floor construction methods, from manufacture to required standards.

How are timber floors constructed?

Timber floor construction consists of boarding supported by timber joists (bridging joists or floor joists) which are nailed to wall plates on their ends and supported by a sleeper or dwarf wall lengthways.

The different types of timber joists.

Timber joists are essential components in many construction projects, providing a framework to support floors, ceilings, and roofs. There are several different types of timber joists, each with its own unique characteristics and applications.

- Solid Timber Joists: These are traditional joists made from solid pieces of timber. They are often used in residential construction due to their relative strength and ease of installation. Solid timber joists can be cut from various types of wood, including pine, oak, and fir.

- I-Joists: I-joists are engineered joists that resemble the capital letter “I” in shape, hence the name. They are made with a vertical web of plywood or oriented strand board (OSB) sandwiched between a top and bottom flange of solid timber or laminated veneer lumber (LVL). I-joists are strong, light, and less likely to warp or twist than solid timber joists.

- Laminated Veneer Lumber (LVL) Joists: These are made from thin layers of wood that are glued together under pressure. LVL joists are strong and dimensionally stable, and they can be produced in lengths that exceed those of traditional solid timber joists.

- Posi Joists: Also known as open web joists, these are a type of engineered joist that consists of a solid timber top and bottom flange with a metal web in between. The open web design allows for easy installation of services like plumbing and electrical systems.

- Glulam Joists: Glulam, or glued laminated timber, is another type of engineered wood. It’s made by glueing together multiple layers of timber under pressure. Glulam joists can carry greater loads over longer spans than solid timber joists and are often used in both residential and commercial construction.

- Parallel Strand Lumber (PSL) Joists: These are made from long, thin strips of wood that are glued together. PSL joists are incredibly strong and often used in areas where high load-bearing capacity is required.

- Composite Joists: These joists are made by combining timber with other materials, such as steel or concrete. This can improve the joist’s strength and other properties, such as resistance to fire or insects.

- JJI-Joists: These are built with a web made from OSB (Oriented Strand Board) and flanges made from solid timber or Laminated Veneer Lumber (LVL). They have an “I” shape, similar to steel I-beams, which gives them excellent strength and stability.

Floor cassettes

When it comes to speeding up production, improving health and safety on site, using fire break materials, reducing waste materials and conforming to robust details. Pre-manufactured floor cassettes are becoming commonplace within timber floor construction.

Cassettes are manufactured using a combination of l-joists and decking materials (OSB/chipboard/plywood) and even come with lifting straps for safe lifting.

Sleeper walls

Sleeper walls are typically 10cm, thick and honey-combed; made to reduce the pan for the floor joists. These sleeper walls seldom have space and are honey-combed to enable free circulation of air in the space below the floor.

Sleeper plates

Longitudinal timber members (sleeper plates) are fixed on the top of these sleeper walls. They are secured to sleeper walls using nails.

Below the wall plates is a damp-proof course layer which is laid immediately to prevent the rising of dampness throughout the process. The hollow space between the flooring and oversight concrete also helps to keep things dry and fully ventilated.

Timber floor standards

During the manufacturing process there are specific standards timber floor construction has to go through in order to meet specific regulations. Standards include:

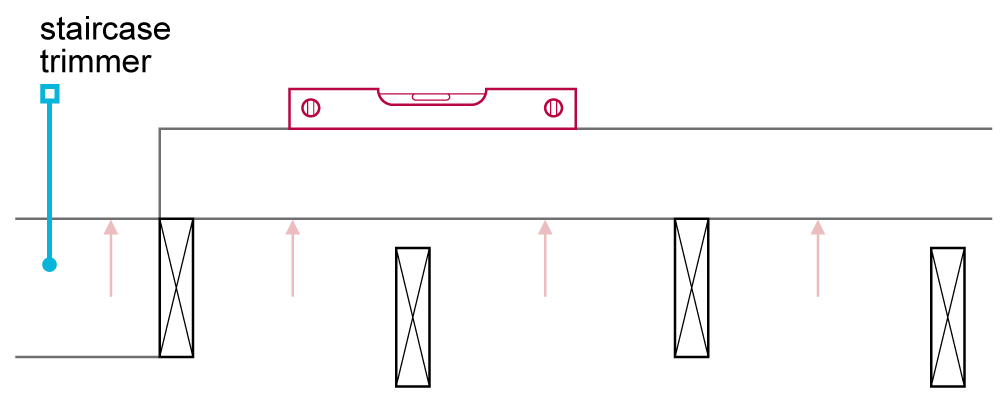

Levelling

All bearings, along with the concrete floor should be level.

⦁ From the staircase trimmer and trimming joist.

⦁ In accordance with the manufacturer’s recommendations or instructions.

⦁ Hard packing should be used – loose or soft packing should be disposed of.

Joist spacing and clearance

⦁ Spacing should be in accordance with the design and not increased or decreased in any way.

⦁ Space should be calculated in correlation to the amount of decking material to be used.

⦁ Joist spacing and clearance are usually a maximum of 600mm.

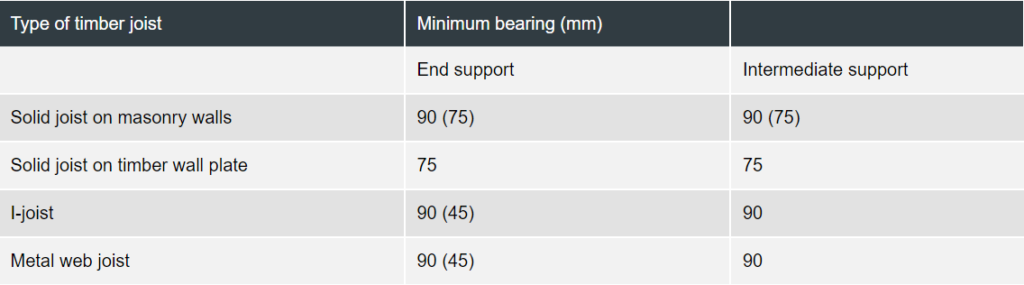

Support

The floor should have an adequate bearing on the supporting structure.

⦁ There should be no restraint on the supporting wall.

⦁ Joist and metal web joists should not be built into solid external walls.

⦁ The support reaction should not exceed the recommended value specified by the manufacturer.

When there are concentrated loads:

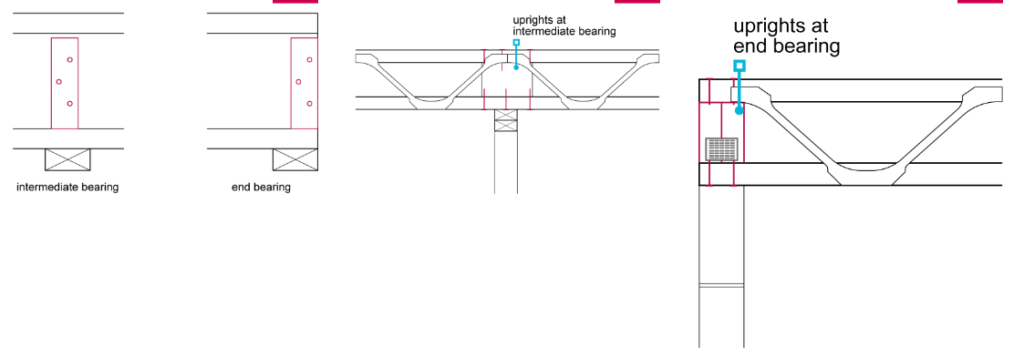

⦁ web stiffeners should be used for I-joists.

⦁ uprights between the flanges, held in place by punched metal plate fasteners or bottom chord (flange) support, should be used for metal web joists.

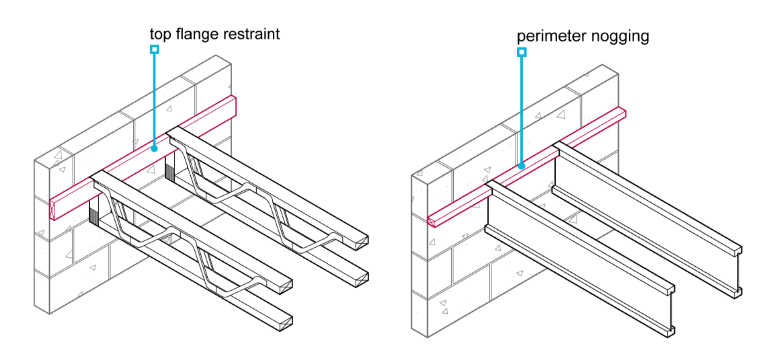

Where joists are used to support walls, noggins will be required at the top flange along the wall in order to support floor decking. Then the bottom flange supports the plasterboard ceiling.

Where joists are not built, blocking should be provided at the joist bearing – this blocking fixes the plasterboard and floor decking.

Timber floor construction methods

Timber floor construction methods can be divided into two main categories: suspended timber floors and solid timber floors.

Each method has its advantages and drawbacks, and the choice depends on factors such as cost, insulation, and site conditions.

Suspended Timber Floors

Joist-and-Beam System:

This method involves the use of timber joists (horizontal members) supported by beams (usually wooden or steel). The joists are typically spaced at regular intervals, and floorboards or other decking materials are fastened to the top of the joists to create the floor surface.

Platform Framing:

In this method, floor joists are attached to the wall plates, and the floor sheathing is laid on top of the joists. This creates a continuous platform, which provides lateral stability to the structure.

Trussed Floor Systems:

These systems span more distances than traditional joist-and-beam systems using engineered wood trusses. Trusses can be custom-designed for the specific project and allow for efficient use of materials and faster installation.

FAQ

How thick is a timber floor?

The thickness of a timber floor depends on the timber floor construction details and materials used, as well as the intended purpose of the floor. Please read below for some general guidelines:

Suspended Timber Floors

Joist-and-Beam System:

The thickness of the timber joists usually ranges from 1.5 to 2 inches (38 to 50 mm), while the floorboards or decking materials on top can vary from 0.5 to 1.25 inches (12 to 32 mm).

Platform Framing:

In this method, the thickness of the floor sheathing is typically around 0.5 to 1.25 inches (12 to 32 mm), with the joists having a similar thickness as in the joist-and-beam system.

Trussed Floor Systems:

The thickness of engineered wood trusses can vary depending on the design, but generally, they range from 2 to 4 inches (50 to 100 mm). The floor decking on top typically has a similar thickness as in the other suspended floor systems.

Considering timber floor construction for your home or business?

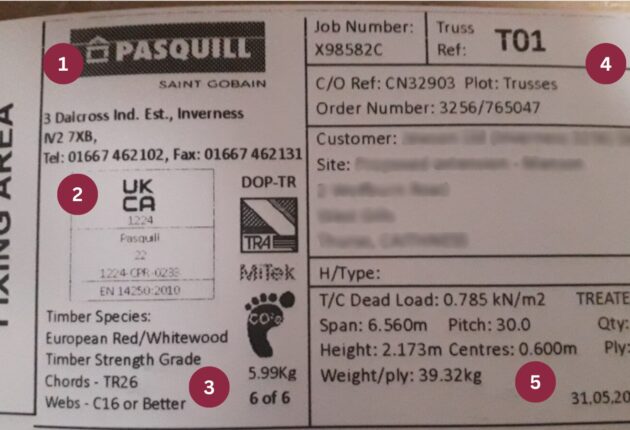

Now you know all about timber floor construction details, what are you waiting for? At Pasquill we are here to help you every step of the way, through highly trained staff and the latest technology – we are everything you need.

Have you got any more questions or are looking to transform your home or business flooring using our joists and cassettes? Contact our experts today.