10 Reasons Why Trussed Rafters Make Sense

When looking at roofing solutions for a build, trussed rafters can offer a myriad of benefits. They are made from strong timber, joined together with durable steel nail plates and are ideal for both commercial and domestic structures.

Otherwise known as roof trusses, trussed rafter roofs are robust and reliable, providing a triangular shaped structured framework to support roof fabric.

Here are 10 reasons why they make life so much easier on-site when compared to traditional cut roofs:

1. Safety

The use of prefabricated trussed rafters allows contractors more control over health and safety standards on-site. This provides more protection to employees who are spending long amounts of time working at heights while handling difficult materials.

2. Speed

Once trusses arrive on-site, we use our specialist crane equipment to off-load, making it a much quicker safer alternative to manual offloading. Installation of the units is also much faster when compared to traditional methods, reducing overall construction time and cost.

3. Cost

Trussed rafter roofs give the user peace of mind, thanks to a stable and pre-determined cost that are unlikely to change due to unseen circumstances. Also, thanks to the pre-built and offsite nature of trussed rafters, there won’t be a need for additional raw materials to be cut on-site.

4. Consistent high standards (offsite)

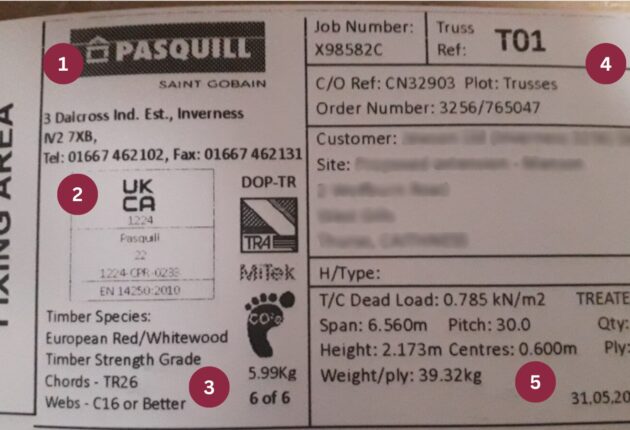

Trussed rafters are highly engineered products manufactured in factories to exact and precise specifications before they are then shipped to the site for use in a wide range of building types. Because our products are built off-site, there is a huge increase in the standard and quality of the product, rather than it being constructed onsite exposed to the elements and might not also be as precise.

5. Quality

Thanks to the fact our trusted rafter roofs are strong and robust, they have the capacity and capability to be incredibly versatile. All our timber products come from independently verified, legal, well-managed and sustainable forests and the timber strength grade for trussed rafters is special – TR26.

6. Sustainability

Not only do trussed rafters add value through off-site construction, but the sustainable nature of the product is also hard to deny. Pasquill’s trussed rafters are created using FSC® certified timber from supporting sustainable forestry. Throughout the manufacturing and delivery process, we work to reduce the levels of emissions and impact on the environment as part of our journey to carbon zero by 2045.

7. Bespoke

Innovating and eye-catching designs are made possible with trussed rafters, as their sizes allow for much greater spans that can accommodate both simple and complex roof structures meaning they can fit any shape build at most sizes. No matter how intricate or technical the design, Pasquill will be able to provide the right solution for you.

8. Delivery times

Construction offsite makes deliveries easier as the number of trips previously required for raw material to make it to the site are reduced and made easier with prefabricated roofs that can be easily craned into place onsite.

9. Skills

Using trussed rafter roofs in offsite construction means trained craftsmen are no longer needed on-site to guide the production step by step and instead can work on more projects from within a factory, thus improving overall time and cost.

10. Versatility

One way that highlighted how our trussed rafters can be used was featured in a project on the Isle of Harris. This project included the use of roof trusses that had to conform to the complex and intricate design requirements, but the use of trussed rafters made the process smoother and ensured a strong roof structure that will last. Explore our case studies to learn more about the variety of ways trussed rafters can be used.

For more information about Pasquill trussed rafters, visit our Roof Solutions page or contact us for a quote today.