The Process of Using An Off-Site Roof Truss Manufacturer

Roof trusses are the most widely used framing in the UK as they provide a cost-effective and flexible design solution. This type of framing helps to turn an architectural vision into a working roof structure.

Roof trusses reduce the amount of time spent installing the structural elements of the roof compared to traditional build methods. An experienced carpenter may be able to install roof trusses in around a day whereas a traditional method of rafters can take as much as a week to install.

If you’re thinking about installing roof trusses within your project, here’s the usual process from design to delivery.

Step 1: Get in Contact With The Roof Truss Manufacturer

The first stage is to contact your preferred roof truss supplier and let them know what you have in mind for your project. Builders merchants such as Jewson and Gibbs & Dandy use Pasquill as their approved supplier. Our design experts are happy to supply all the technical knowledge to the customer direct should they require it, given that suppliers are happy for the customer to speak to us.

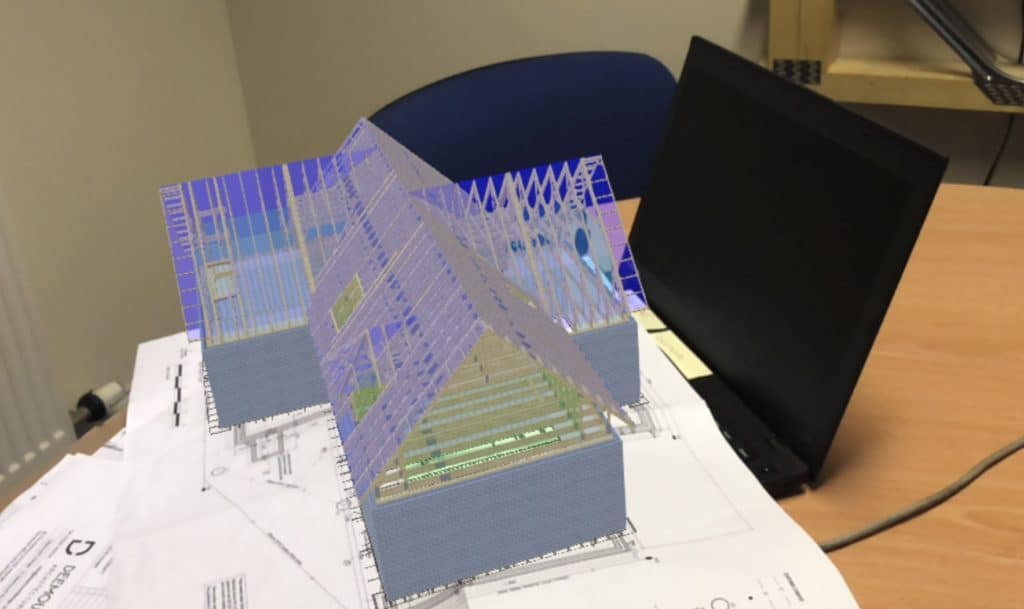

Step 2: Design

Once you’ve found a roof truss manufacturer that you would like to work with on your project, their local design team will then be in touch to discuss design and project specifications. They may even recommend that a site visit might be needed to get a better visual and they may be able to present you with a 3D visualisation of your project and roof truss design.

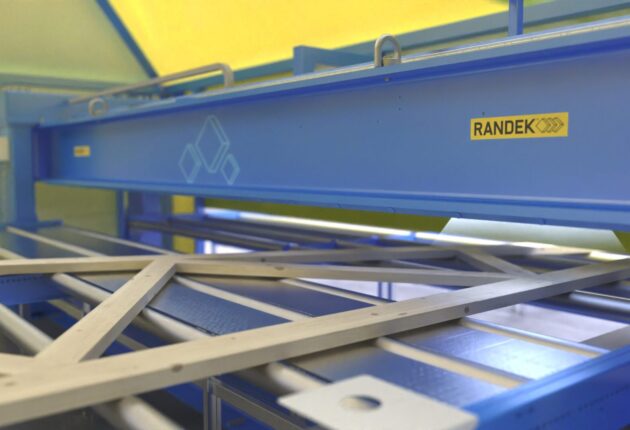

Step 3: Manufacture

Once an on-site visit has happened and the roof truss manufacturer is sure of your design and specifications, your roof trusses will start to be manufactured within a specially designed warehouse. Roof trusses are usually created using a specially designed software helping to create accuracy when cutting your roof trusses.

Step 4: Supply

Once the manufactured process has been completed, your roof trusses will be delivered to you on-site and are ready to be safely unloaded using a crane. Once this has been done the roof trusses are ready to be installed safely using a crane which will save you both labour and cost. However, if there isn’t a crane available, all attention should be directed to gently lifting the truss with ropes to avoid damaging the roof trusses.

Benefits of using a roof truss manufacturer

1. On-site design and measuring service

Roof trusses manufacturers can visit you on-site to take measurements and talk to you personally about any technicalities of your designs. This will help with a quicker and simpler installation.

2. Enhanced technical possibilities

Are you planning a design which might seem impossible using traditional methods? This is why roof trusses have the advantage as they can be created around a complex layout.

3. High levels of construction accuracy

With the recent introduction of laser technology, roof trusses can now help to make sure they are creating to the specification.

4. Saves on construction time

Thanks to the roof trusses being built off-site you can continue with your on-site work. Once the roof trusses have been created they can be installed straight away no matter the weather conditions.

5. Reach those hard to reach areas

As well as offering articulated vehicles, suppliers such as Pasquill offer smaller vehicles to help get the products to those hard to reach construction sites.

Side Note: Schedule enough time for the building and delivery of engineered products, don’t leave it until building work reaches the roofing stage to get a quote as the design and manufacturing process can take some time. Choosing the right roof trusses manufacturer is an important step in your construction. You need a reliable and trustworthy manufacturer. At Pasquill, we aim to make getting the roof trusses that you need as easy as possible. Get in touch with our team to find out how we can help with your next project.