Pasquill Invests In New Technology

August 2015

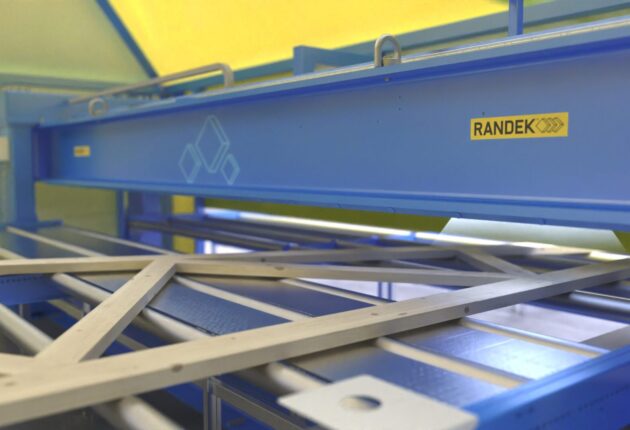

Pasquill, the UK’s largest supplier of roof trusses, continues with its investment programme by purchasing a state of the art laser projection system from A V Birch – a leading manufacturer of Timber Engineering machinery – for its Redhill manufacturing plant as part of the company’s overall strategy to increase productivity and enhance quality control procedures.

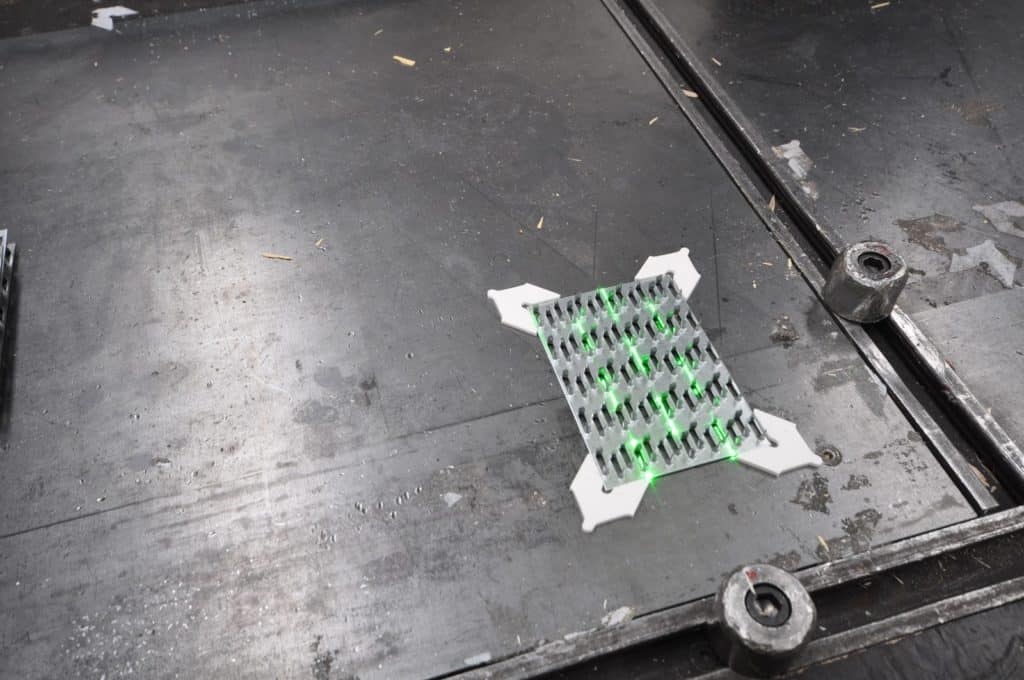

The new technology, which uses laser light patterns to create work templates, has increased the site’s truss assembly capacity, through the reduction of setup and cycle times.

The system works by converting design files of roof truss configurations into a full-scale laser image on a manufacturing ‘table’ surface. Jigs are then accurately set using the laser projected truss outline and components quickly identified and placed into position. Nail plates can then be precisely positioned on component joints to ensure maximum strength and optimum quality control.

The British standards code of practice for trussed rafter roofs EN14250/BS5268 requires plate positioning to a tolerance of 10mm, however the new design software allows Pasquill to work to a tighter tolerance of 5mm, which is above and beyond the industry standard.

Commenting on the system, Gabriel Prior, Pasquill’s Regional Operations Manager said: “In addition to improved productivity and quality control, we have also introduced a new training programme for new operatives to help them understand the technology and ease of use. The new system allows us greater flexibility so that we can react more quickly to increased customer demand.

“We have introduced two laser systems in Redhill, and the resulting continuity in our quality control has been excellent. We are now ready to roll out the new laser technology system across our other manufacturing sites around the country.”