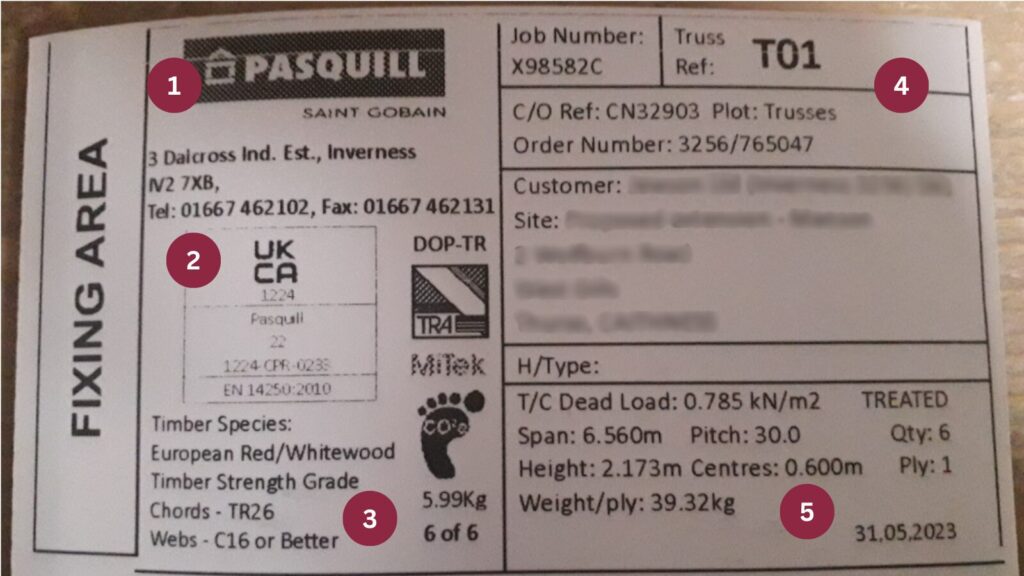

The Product Identification Label – helping to futureproof roofing & flooring solutions.

One of the ways we ensure consistency and traceability across our projects is with the Product Identification Label, located on our engineered timber products. The label will separate all the key information about the timber used in the product construction, and tells future construction workers and designers everything they need to know about the materials that have been used. This label is also water and weather proof making it durable and reliable.

Below, we take you through what each piece of information tells us, and how it can be useful for future construction.

1. Attributed Design Centre/Manufacturing Site

We have Design Centres and manufacturing sites across the UK, so whichever team supplied the roofing or flooring solution will have their details on the top of the label which includes their telephone number and address.

Easily identifying the team associated with the product can help to push future projects forward as contractors can more easily track the product’s origins and contact the team for any assistance they may require. They can also help anybody who works on the project in the future ensure products are up to any new regulations that may be implemented.

2. Certifications

Pasquill holds several certifications that are key across all timber builds, and these are outlined on the label.

UKCA: The UKCA marking is proof that this timber has been tested against UK standards and meets product requirements and relevant legislation.

CE marking: At the bottom of the label you’ll see the CE marking showing the timber has been tested against the relevant European standards. You’ll see this stamped on our all our engineered timber products.

MiTek: This shows there is an attributed design to the trusses and that it has been accurately constructed to that design.

TRA: Having this stamp shows Pasquill’s membership to the Trussed Rafter Association, which ensures suppliers are providing quality trussed rafter roofs and metal web joists that meet professional standards.

Access to this information will help future construction personnel track the regulation standards that have been met, and shows the timber within a build is up to code. Inspections are key for buildings to ensure they meet building regulations and are safe for residents.

3. Timber type specifications

Included on the label is the timber series that has been used in the construction of the product. This is important to specify as it can help future contractors match new timber for any necessary replacements or extensions.

The timber strength grade is also detailed for chords and webs. Having this strength grade can make matching timber easier. Our timber is sourced from Scandinavia where the growth is slower and creates tighter internal rings, resulting in more durable timber. The typical strength grades are C16, C24 and TR26, with the latter being used only for the manufacture of trusses.

The kg weight associated with CO2 for timber typically represents the amount of carbon dioxide (CO2) emitted during the life cycle of the timber, from harvesting and processing to transportation and installation.

4. Customer details and job reference

The top right-hand side of the label records the job reference number, plot number and customer details. Within this section, you’ll find the order number, project reference, and products included within the order. In the large box underneath, typically, you’ll find details the customer’s name and the project address. This helps to clarify where the product manufactured are going and can help future contractors discover who was responsible for the project. This is also a good way for Pasquill, customers and third parties to identify order codes and product types.

5. Dimension specifications

The final section of the Product Identification Label details the dimensions specific to the construction project.

In this section, you’ll typically see deadload weight including other elements such as roof coverings and supporting elements. You will also see the span, pitch and height of the trusses, the distance between the centres of the trusses and their weight.

The sticker will also tell you how many trusses have been provided as part of the order, the ply of them, and whether the trusses have been treated. In the bottom right-hand corner, you will find the manufacturing completion date.

To learn more about these terms, and more common construction terms, please visit our glossary blog.

Having all this information readily available comes with a host of benefits, making future jobs and tracking much easier. The Product Identification Label helps to avoid mishaps, makes inspections easy and allows for the timber type and grade to be easily matched for future renovations. It can help eliminate the headaches of building on an existing timber project.

Please get in touch or Request a Quote from your local Pasquill Design Centre for high-quality service on your next project.