The future of sustainable housing design: Pasquill’s off-site timber components help deliver zero-carbon concept home

At Pasquill, we’re proud to be part of a pioneering project that’s driving progress towards low carbon and net zero housing. The eHome2 project is a three-bedroom concept house built using a combination of off-site construction and materials supplied by us and our sister companies within Saint-Gobain UK & Ireland.

The innovative home was built inside the globally unique £16m Energy House 2.0 climatic chamber facility at Salford University. From March 2023, the home will undergo rigorous whole-building testing over a period of nine months – including thermal performance, energy efficiency, running costs, and residential comfort. It will also be tested for its ability to cope with extreme temperatures and climatic conditions.

The eHome2 project is a collaborative partnership between housebuilder Barratt Developments, Saint-Gobain Off-Site Solutions and additional brands within the Saint-Gobain UK & Ireland group. It aims to change the way we build high-quality, sustainable, and future-ready new homes in the UK.

Playing our part in sustainable housing design and innovation

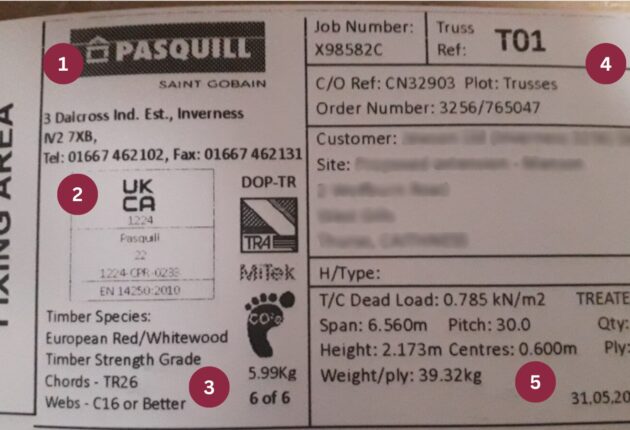

Pasquill played a crucial role in the project, supplying timber-engineered components such as Floor Cassettes and Roof Trusses, manufactured and assembled at our flagship site in Chorley. These add to the sustainability credentials of the build, which is designed to exceed the upcoming Future Home Standards regulations.

These top-hung Posi-Joist™️ floor cassettes create a larger service void that allows for easy routeing of utilities throughout the home. They help speed up the installation process and reduce thermal bridging at wall-floor interfaces.

Additionally, we supplied the Roof Trusses for eHome2 to help create a thermally efficient attic space. By combining traditional trusses with Attic Trusses, we created a space that can accommodate additional services and pipework required to run future smart homes.

The next generation of homes

The eHome2 project is a fantastic demonstration of how off-site manufacturing can deliver high pre-manufactured value to housing developers, showcasing how innovative design solutions driven by sustainability and performance can help make the world a better home.

Technical and Development Director Tom Cox (R) at the eHome2 launch.

Ross Baxter, Managing Director, Saint-Gobain Off-Site Solutions, said: “eHome2 is an investment in the future of UK housing, and has the potential to completely revolutionise how we design and build homes. The fact so many organisations are working together towards a common goal shows that collaboration undoubtedly is the best way for us to tackle the challenges facing the industry.

“It’s our aim to help national housebuilders and other volume housing providers find a way of delivering zero-carbon homes of the future at scale and speed. The project is a brilliant showcase of how off-site manufacturing can help achieve this, with innovative solutions driven by sustainability and performance that can help make the world a better home.”

At Pasquill, we’re proud to be part of a project that’s shaping the future of sustainable housing design in the UK, and we’re excited to help national housebuilders find a way of delivering zero-carbon homes of the future at scale and speed.

We’ll be back to update you soon with the results! For more information, visit www.saint-gobain.co.uk/eHome2