COMPLEX CHALLENGE FOR CARE HOME OPERATOR

Project information

- Building description:

- Mansfield Care’s £10m investment in Hilton House, a new 60-bed care facility in Edinburgh

- Location:

- Haddington, Edinburgh

- Client:

- Mansfield Care

Products used

-

Roof Trusses

Services used

-

Design

-

Manufacture

Project overview

As part of a £10m investment, highly regarded Scottish care home operator Mansfield Care embarked on their biggest venture yet, building a three-storey, 60 bed facility in Haddington, Edinburgh.

Mansfield Care currently looks after 12 care homes in Scotland, providing care and support for the elderly community with a resident-first ethos in state-of-the-art

facilities. This will extend to their newest care home, Hilton House.

The new care home will create up to 100 new jobs for the local community and provide around £2m for the local economy each year.

The facility will comprise off six 10-bedroom wings to ensure residents receive the best possible bespoke care. The building will also accommodate a café, hair salon, and a private function room. A wetland will also be created for the residents to enjoy,as well as a pond to encourage wildlife.

Technical overview

Pasquill designed and supplied Roof Trusses to the care home’s main contractors, Hilton House Ltd.

The three-storey care home had a complex roof structure, which evolved as the job progressed. Originally, the client had specified a 30-degree pitch on the roof, but after speaking with Senior Designer Malcolm Duff from our Uddingston Design Centre, they opted to lower the roof to 27.5 degrees.

Lowering the roof to 27.5 degrees meant that the trussed rafters can be manufactured and transported to site without the use of top hats. Additionally, they are also easier to install on site, which saved them time and money. Hilton House required a truss spanning almost 15 metres, so in this project, the roof design incorporated a stub and mono truss, which were then overlapped and nailed together on-site using the internal load bearing walls.

A truss spanning less than 12 metres is normally designed using 35mm timber. Once a project goes above a 12-metre span, a truss is manufactured using 47mm timber.

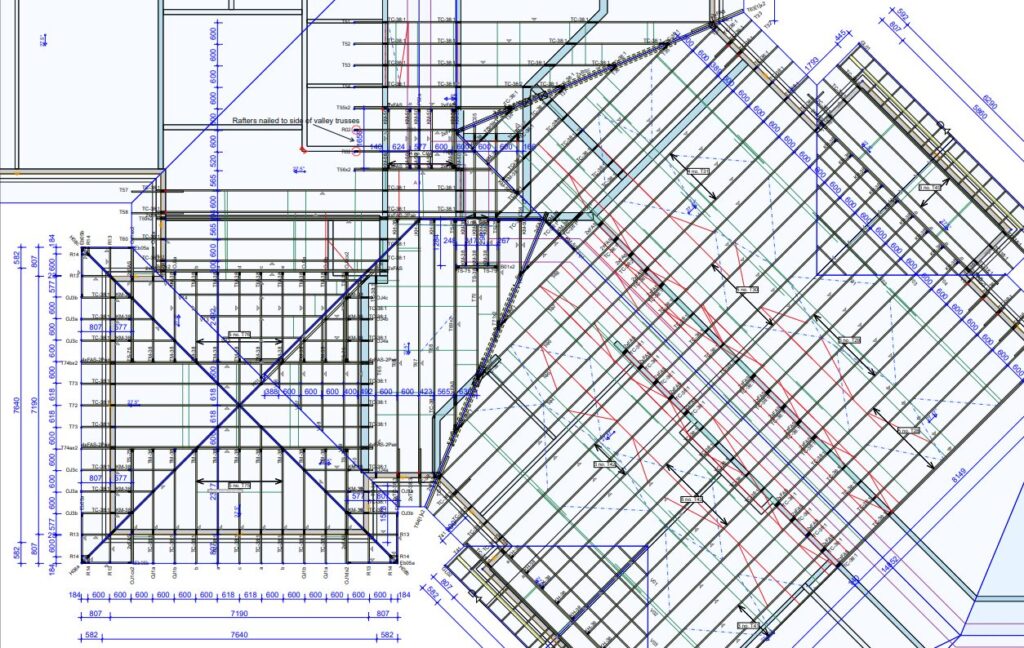

One of the challenges faced by Malcolm was the lack of load bearing walls at the overlaid hips. Unfortunately, not all the internal walls within the home were load bearing, so the solution was to design these areas to incorporate girders to support the main roof.

In larger commercial projects, truss designers often need to take walkways in the roof space into consideration. Walkways allow maintenance workers easier access to services such as ventilation systems, sprinkler systems or solar panels.

The main roof required a walkway through the centre of the trusses, this proved trickier than usual, as there was a skewed section where the building changes direction, the truss design was altered to suit.

In the original design the low-level roof had two dual-pitched roofs, with a flat roof section in the middle. Based on Malcolm’s feedback, the client opted to change to a dual-pitched roof with a 1.5degree flat section incorporated within the truss to help shed the rainwater from the flat section.

As the designs were coming together, Malcolm was able to create a 3D drawing of the Roof Trusses using special software. He was then able to share this with the design team and the client, so they could look around his design to make sure they were happy with the proposal. A QR code added to paper drawings issued to the site allows the on-site team to open the plans up on their phone to see exactly how the trusses go together.

View the 3D drawing designed by Pasquill’s Senior Designer, Malcolm Duff here:

https://www.mitek.co.uk/mitek3d/?3d_id=b337db80-9a3b-4686-a0b0-e11a3e602b64

Senior Designer, Pasquill

“We always collaborate closely with the client to understand their needs for the project, and sometimes, like in this project, we must work around to create cost-effective solutions. It is always interesting to work with both the internal Pasquill teams and the client’s teams to produce a solution that fits their budget but does not compromise on the original plans the client had.”

Business Development Manager, Hilton House Ltd

“I found Malcolm particularly helpful during the design process, and while there was

the odd hiccup, I was happy with the Pasquill trusses when they arrived. I would

recommend Pasquill.”