Project information

- Building description:

- New school building

- Location:

- Okehampton, West Devon

- Client:

- Innovaré Offsite Ltd

Products used

-

Floor Cassettes

-

Roof Cassettes

-

Roof Trusses

Services used

-

Design

-

Express Delivery

-

Manufacture

Project overview

Our Coventry Design Centre supplied design expertise and a range of our engineered timber products to create a purpose-built special needs school building in Okehampton, Devon. The new building was created to provide an opportunity for children in the local area to attend a modernised special needs school.

All pupils who attend The Promise School have specific Education and Health Care Plans (EHCPS) with primary social, emotional and mental health needs. The Promise School delivers support and encouragement to help develop the skills of all its pupils.

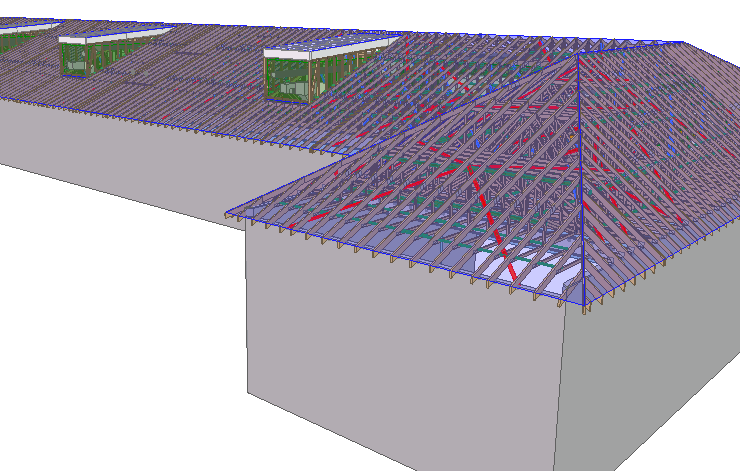

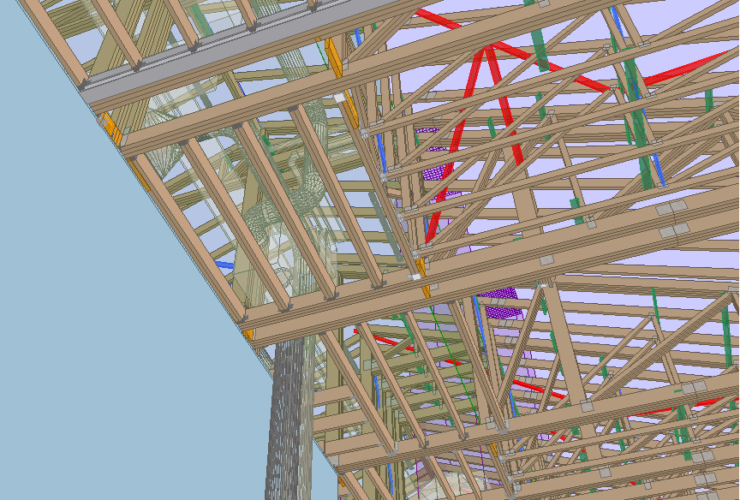

The project was a significant build, with a roof made up of 1,875m3 and 1,255m3 of floor cassettes, and 20-meter Roof Trusses for the main roof. With such an expansive roof and large number of materials required, the deliveries of the products spanned over three months, with the correct products brought to site as and when they were needed.

Matthew Naughton, Delivery Manager at Innovaré Systems Limited said; “We’re very happy with the delivery efficiency from the Pasquill team. The manufacturing team kept us up to date with the delivery schedule and discussed the requirements we had on site. This was a great project to work on with them.”

Technical overview

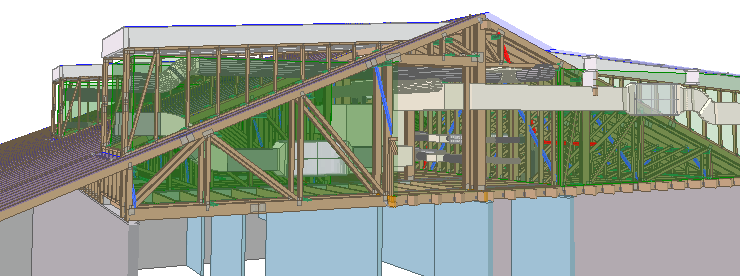

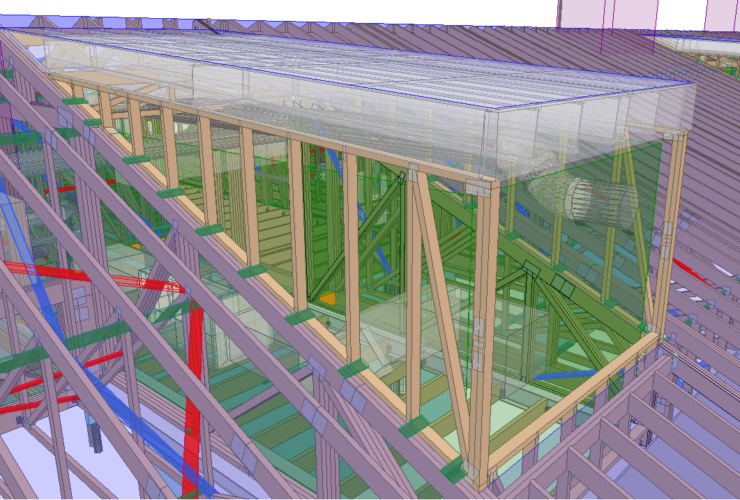

Pasquill worked with the main contractors of the project, Innovaré Offsite Ltd, to design and manufacture Roof Trusses, Posi Floor Cassettes and JJI Roof Cassettes for the new large-scale school project in Okehampton.

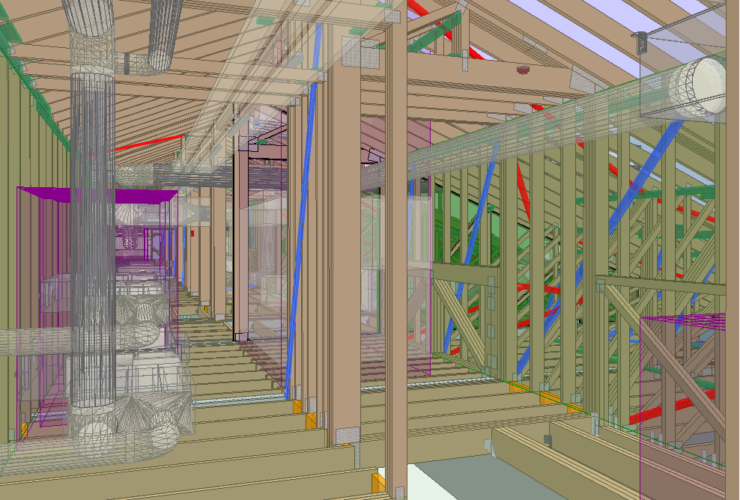

Innovaré Offsite Ltd supplied our design team with an IFC model of their wall panels, enabling us to finalise the design for the floor cassettes and roof trusses. With Innovaré Offsite providing the wall panels, the Pasquill design team worked closely alongside their designers to ensure their walls and our roof designs seamlessly fitted together.

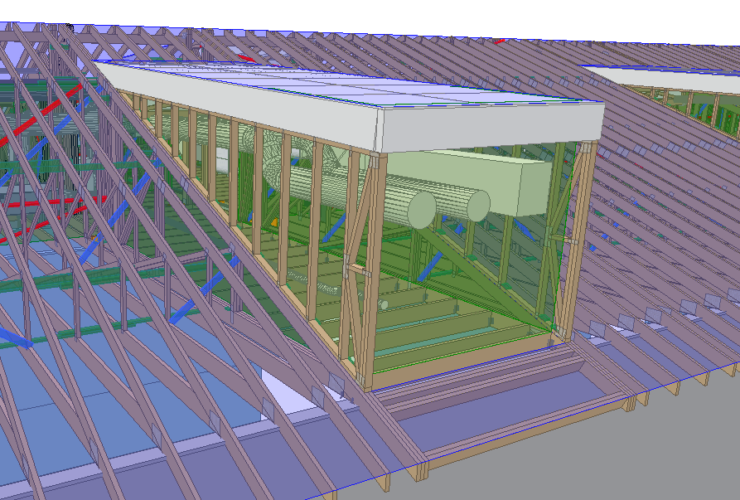

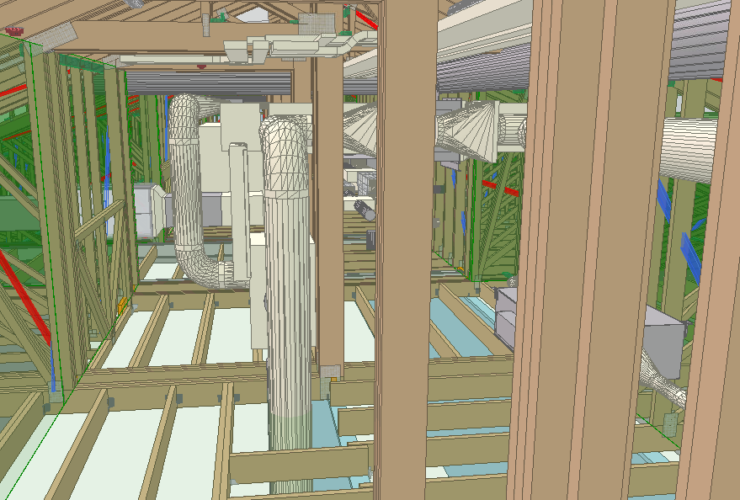

The large loads within the roof space had to be encompassed in the overall design. The team designed around large water tanks, ventilation ducts and air handling units, which are all housed within the roof structure. Working closely with the companies responsible for these units, the team were able to get correct measurements and weight specifications to plan for the roof structure, ensuring it could hold up the loads when installed.

The main roof spanned over 20m, which was split over a central load-bearing wall to support the weight of the roof, as the roof was designed to accommodate all paint and ducting for the school. This was achieved through designing roof sections to be lifted from the ground onto the wall plate, increasing the roof height to create additional space.

Our designers also had to allow additional space for a walkway from one end of the roof to the other, so future maintenance would be easy to carry out within the roof space.

As the size od the project was larger than a typical roof, our team considered how to handle the heavier trusses. The team split the roof into sections to make it lighter and easier to handle, ready to be reassembled on-site.

Another consideration was how products would be transported and handled from the Pasquill Redhill factory to the Okehampton site. This is because the span of the Trusses was larger than normal and needed extra care taken when loading up deliveries.

To further ease the load, the building was split into phases to ensure the correct materials were delivered to site when the customer required it.

By fabricating materials and components off-site, the quality and processes are managed closely, helping to increase efficiency. With fewer deliveries to site, lead times are reduced, and vehicle emissions are minimised.

Pasquill actively promote using certified and legally verified timber products and hold Chain of Custody Certificates for either FSC®, or PEFC (PEFC/16-37-194). By supporting sustainable forestry, we are helping to reduce our environmental impact and increase the sustainable efficiency of the school.

For this project, the Coventry team worked closely with the customer to ensure that every aspect ran smoothly. With a project this size, we made sure to coordinate with the teams on-site to deliver the project effectively and to meet the customer build schedule.

Testimonials

Technical Manager from Pasquill Coventry Design Centre

‘The team at Coventry and myself, were incredibly excited to work on this project to help toward such a great cause to build this special needs school. We’ve built a positive relationship with Innovaré Systems across a range of projects and and have enjoyed working alongside their team.

With a very large roof span, we created precise designs to ensure an accurate result. The team took special care to design each Posi Joist before drawing them into individual cassettes to be manufactured. We’re delighted with the final result and are thankful to Innovaré Offsite for approaching us to work on this project.’

Site Operations Manager, Innovaré Systems Limited

‘It was really good to be working so closely with Donald from Pasquill as he was always available to help with queries. The technical aspects were specifically what we had asked for and the products were high quality and easy to install on-site. Overall, the project ran smoothly with Pasquill as we worked closely with them throughout and the colleagues delivering the solution provided quality customer service.’