The Benefits Of I-Beams For Housebuilders

At Pasquill we are passionate about providing engineered timber solutions that benefit house builders as they build homes.

While our whole range of engineered timber products have been designed to offer a host of benefits, in this blog we’ll be focusing in on I-Beams, or JJI-Joists, to dive deeper into how using these can positively impact build programs and homeowners.

What are I-Beams?

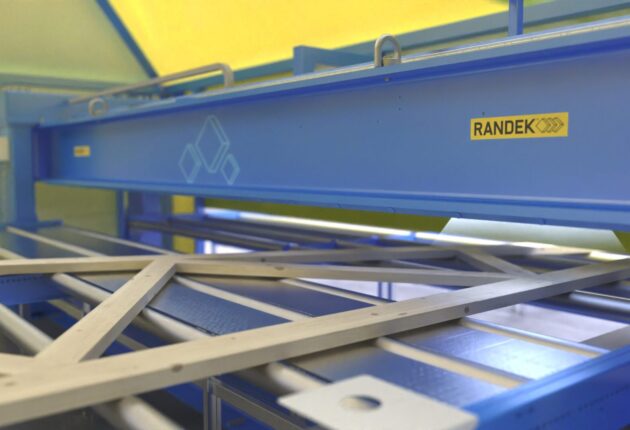

While I-Beams or I-Joists are the generic names for the product, at Pasquill we call them JJI-Joists. This is because they are manufactured by our partner James Jones out of its factory in Scotland, and they are delivered to our factories in batches through their distribution network. They are delivered in 10, 12 or 13.2m lengths and cut down to size based on customers specific project requirements.

I-Beams are an engineered timber joists, which combines 45mm deep softwood flanges with OSB (Oriented Strand Board) to make a strong joist which is quick to install. A range of depths are available, from 195mm to 400m, offering more flexibility for builders. Additionally, the joists we use are the only I-Beams certified to PAS 2050, which allows architects, specifiers and builders to view the full embodied carbon data. This is particularly pertinent as the world moves to building more sustainable homes with a reduction in carbon.

I-Beams are most commonly used for flooring, but can also be used for low-pitched roofing, and even vertically in wall applications. For example, at Saint-Gobain Off-Site Solutions’ eHome2 project in collaboration with the University of Salford, we supplied JJI-Joists to the Thermistud closed timber wall panel solution

What are the benefits?

Reduced snagging

It’s all too common to hear floors squeaking and creaking in new homes. This happens when the moisture content of the timber used in the flooring drops as it is exposed to ambient temperatures, which causes the timber to twist, shrink in size and begin to squeak.

When using JJI-Joists in flooring, the initial moisture content in the softwood flanges is much lower, meaning there’s much less opportunity for the moisture content to change. When the home warms up, the timber used in JJI-Joists doesn’t shrink or twist, significantly reducing the opportunity for squeaking floorboards.

Snagging reports carried out on behalf of the homeowner are likely to pick up on creaking floorboards, therefore costing the housebuilder both time and money to correct. By specifying JJI-Joists, housebuilders can build homes safe in the knowledge that flooring won’t be an issue.

Controlled manufacture

JJI-Joists are also manufactured in a controlled factory environment, which helps maintain consistency within the product. When you choose JJI-Joists, builders can be assured that they will be delivered to site exactly as specified in the design, and can slot directly into place on-site with little need for adjustment, while reducing on-site waste.

Easier installation

Typically, a traditional flooring joist would encompass herringbone struts, which provide bracing between parallel rows of joists to prevent them from twisting. With JJI-Joists, these are not required, making them quicker to install with no special tools required.

Improved service access

Thanks to the 9mm OSB web in the centre, it’s easier for wiring, plumbing, mechanical ventilation and heat recovery systems to pass through. There are specific areas that can be drilled through to accommodate these services, without having a detrimental effect on the I-Beams’ structural performance.

Compliance and sustainability

I-Beams are manufactured from FSC® certified timber, ensuring all materials originate from responsibly managed forests and other controlled materials. They are compliant with Approved Document E: Resistance to Sound legislation, while also achieving both 30- and 60-minute fire resistance certificates.

If you’d like to find out more about how you can use JJI-Joists in your next project, contact us today or request a quote from your local Pasquill Design Centre.