Pasquill invest in automation with Randek Autoeye

At Pasquill, we are always looking for new ways to deliver our engineered timber products quickly and safely, to ensure our customers are getting the very best service.

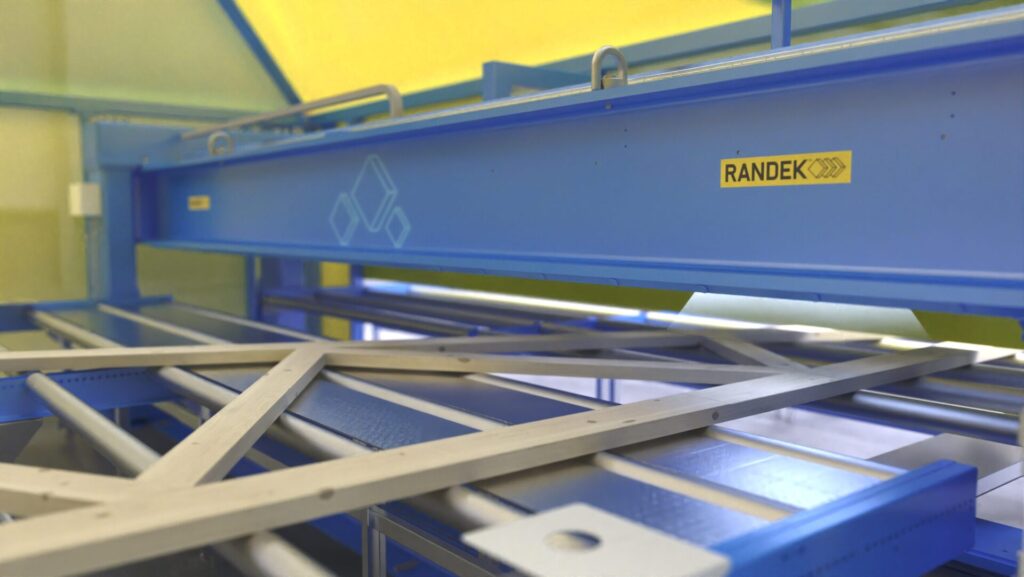

Last year, we shared the news that we were investing in Swedish company Randek’s AutoEye automated truss manufacturing system, which would allow us to increase capacity from our Redhill site while also improving safety and productivity.

Work is now underway in Redhill in readiness for the installation of the AutoEye, which is due to be installed in November 2024. The £4 million investment will see the installation of the AutoEye system, which will boost the capacity of trusses manufactured from the site while allowing more complex trusses to be produced in significantly less time.

As part of the £6 million overall investment, our Stoney Stanton site in Leicestershire has received production of Posi-Joists and JJI Joists, which have been moved from the Redhill site to create space for the AutoEye machinery.

How will AutoEye help to increase our capacity?

The AutoEye system helps to streamline the production process by visually identifying the joints in the truss, then picking, placing, positioning and pressing the nail plates with the required force, which is determined by the machine. The AutoEye system will offer up to a 50% time savingduring manufacturing, which will support demand during peak periods.

Its semi-automated setting process will ensure the quality of our trusses remains high, as human interaction is still required during the early stages of manufacture. With a long-standing construction skills shortage in the UK, it is hoped that automating the truss production process will free up workers at the Redhill site, allowing them to continue with other projects within the business.

Until now, our Redhill site has been operating at full capacity, but the introduction of the AutoEye technology will see the site significantly expand its capabilities, allowing for approximately double the output for the same amount of labour.

AutoEye and its safety benefits

The introduction of the AutoEye will also increase safety within the factory, as it will reduce the amount of manual labour required by our team, with the bulk of the truss production process controlled by the AutoEye Truss System. With zero manual set-up required, trusses produced from the Redhill site will be more accurate and manufactured well within the recommended tolerances.

Its automated plate placement and pressing, combined with a nailing bridge system removes the need for working at height, further increasing safety for our site teams.

We’re excited to share the AutoEye journey with you all and look forward to providing further updates on the project as it progresses.

If you would like to discuss how we can help your next project by providing high-quality Roof Trusses, please get in touch or Request a Quote from your local Pasquill Design Centre.