Deconstructing the Timber Frame Extension

As one of the key brands making up the Saint-Gobain Off-Site Solutions division, it’s hardly surprising that we’re advocates of this innovative type of construction. However, there is extensive research backing up our enthusiasm for off-site manufacturing (OSM), proving that it is often a safer, eco-friendlier, quicker and more affordable way to build.

This is because manufacturing building components in a controlled factory environment will almost always produce better results than relying on traditional on-site methods alone. Plus, the need for many of the most dangerous tasks, such as working from height, is removed – making it safer for everyone.

But while OSM is being rolled out en masse at building sites across the country, it’s also perfect for smaller bespoke builds too. Take for example our Pasquill Timber Frame Extension, which we believe is the perfect application for off-site construction, ideal for both residential or commercial properties looking to increase floor space.

What’s included in a Timber Frame Extension?

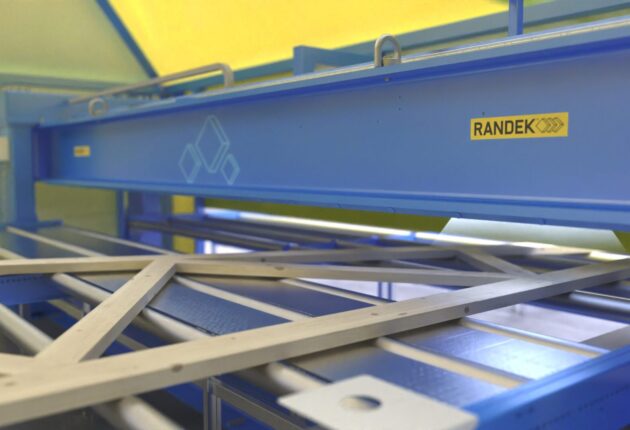

As part of our service, we supply a timber superstructure engineered to the exacting specifications required. These components are then delivered, ready for installation and follow-on trades such as electrical and mechanical – making it a much quicker process than brick and block extensions.

During the design stage we will provide your architect and engineer the line and point loads that the timber frame transfers to the foundation to ensure that they can design and specify the correct foundation detail. Our engineer package also contains all the calculations that you will need to submit to your local authority building control for our timber frame element. We will also specify the connections on how the timber frame walls fit to your existing property.

As leading suppliers of roof trusses and joists, we’ll also be on hand to deliver any additional calculations required for these products, depending on whether the project is a single or two-storey build.

The timber we use is supporting sustainable forestry with either PEFC or FSC®, certification and is treated to protect it from beetle infestation and rot. Typically, one of our extension products will consist of 38×140 CLS external wall panels and 38×90 CLS internal wall panels.

What regulations do I need to be aware of?

Before you start planning your Pasquill Timber Frame Extension, you’ll need to ensure that you have the correct planning permission in place. The good news is that extensions of this size often fall under Permitted Development Rights.

This means that if your proposed extension meets specific criteria in terms of size and position, then you might not need planning permission – but if in doubt, speak to your architect or council planning officer.

When your project is finished, it will still require full building regulations approval. Thankfully, our digital design practices and expert timber frame engineers can produce the calculations required for your Building Control submission.

We specialise in supplying the superstructure of a Timber Frame Extension, ready for installation and follow-on services. Each project is completely bespoke, designed and engineered to dovetail with your existing property.

Is a Timber Frame Extension right for me?

David Pope, Design Office Manager at Pasquill Coventry, leads the Timber Frame Extension projects across the business. He said: “Our team is made up of very experienced timber designers, who are used to working with architects and structural engineers to create the structures that will seamlessly and safely join onto an existing property.

“Our customers range from small builders to merchants and self-builders, all of whom have benefited from the increased speed and reduced cost that OSM can deliver compared to traditional extensions. What’s more, as part of the trusted global Saint-Gobain group, they could rely on the guarantee outstanding service, from design through to delivery.”

As each Timber Frame Extension we produce is completely bespoke, the best way to find out more is to get in touch with one of our expert designers, who will be happy to draw up a quote just for your project. Our lead times are two-three weeks for an enquiry, and eight weeks between placing an order and delivery. Alternatively, read more about our Timber Frame Extensions.